MONOFILAMENT EXTRUDERS

Please click on the You Tube™ Link below to watch a short video on the Line Supervisory Control and Monitoring System.

Monofilament Extruder with EtherCAT Communication.

Monofilament Extruder with Modbus TCP/IP Communication.

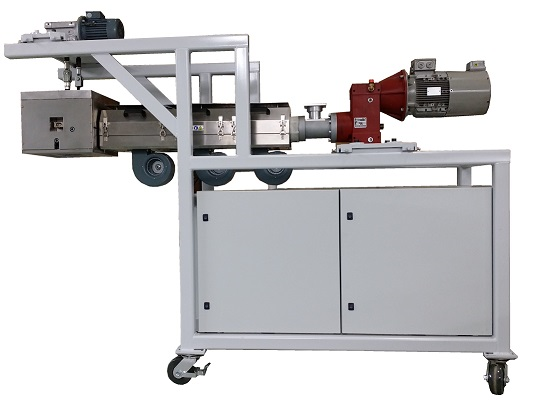

Monofilament Extruder

We build and design custom-made extruders for a wide renge of gauge monofilament.

With One Spin Pump

With Three Spin Pumps

Portable R&D System

Extruder Pressure and Temperature Zone Controller

We manufacture a variety of control systems that are dependable, user-friendly and networkable (Modbus TCP/IP) for pressure and temperature control applications.

Price:From $15,880 and up depending on the configuration and Temp. Zones

Area of use:

· Extruders

· Spin Pumps

· Draw Stands

· Quench Baths

· Ovens

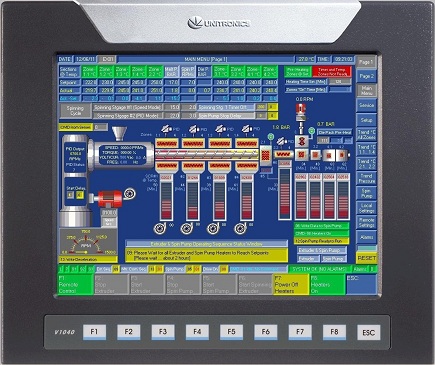

The compact MZT101 multi zone temperature/process controller is extremely versatile and user friendly. Very useful when it comes to rebuilding of extruders and downstream extrusion equipment. The machine operator needs to review only those parameters relevant to the particular application (extrusion process) during setup. A graphical touch screen and pre programmed function keys display offers optimum process information at a glance. The display identifies the status of outputs, alarms, digital communications (Modbus TCP/IP), and special options. Up to 24 built-in PID loops, including internal auto-tune, ramp-soak programmer and bumpless transfer. Use MZT101’s PID loops to economically and efficiently combine accurate process control with the flexibility of a PLC. Use MZT101’s smart data tables to log dynamic data and to store production recipes. 120K for recipes parameters, datalogs, etc’ and 192K for read-only data, ingredient names, etc’. Simply scroll between pre-programmed recipes or menus, using arrow keys or touchkeys. This enables you to choose and activate a desired task via the HMI immediately, on-site. Press the touchscreen for a few seconds to enter the PLCs Information Mode, providing you with powerful diagnostic capabilities.

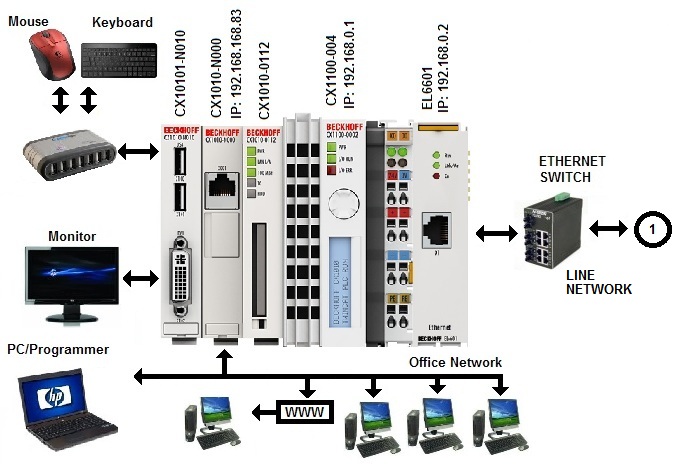

LSC-6CE Line Supervisory Control and Monitoring System

Our LSC-6CE is a user friendly and simple to operate control system that manages the complex control logic of each machine to smoothly control the whole monofilament extrusion line resulting in waste reduction and lower production costs. The complete extrusion line operation parameters are monitored and controlled from this unit.

•InduSoft Web Studio on Windows CE 6.0 Operating system

•Main Controller: Beckhoff CX_1010 or CX_1020(Optional)

•Remote Machines: Unitronics Vision1040 and Vision560 ... powerful PLC with a built-in HMI

•Comprehensive reporting

•Completely scalable

•Alarm logging

•Historic trending for sophisticated data recording

•Recipe management and storage

•Users can easily connect to any SQL database

•Multi Level security system

•Networkable

•Web accessible

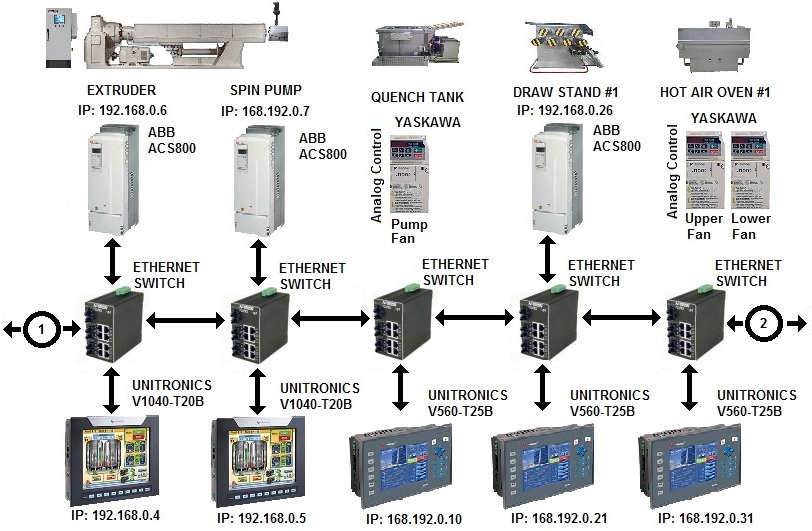

LSC-6CE Control System & Downstream Equipment

Extruder and Downstream Equipment...part 1

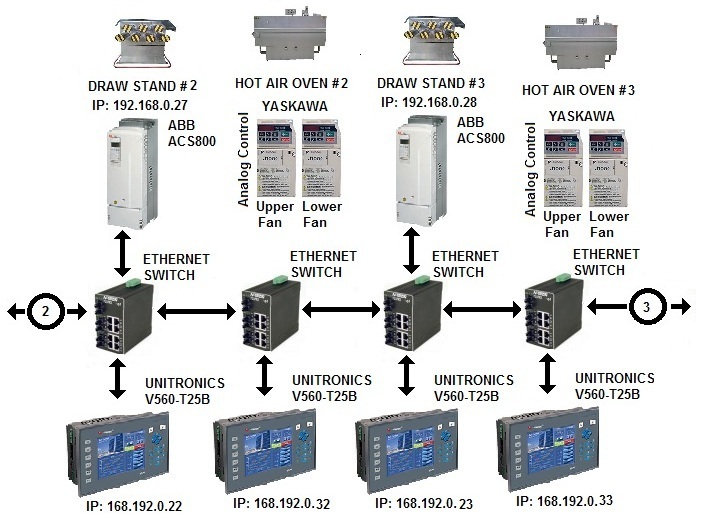

Downstream Equipment Continue...part 2

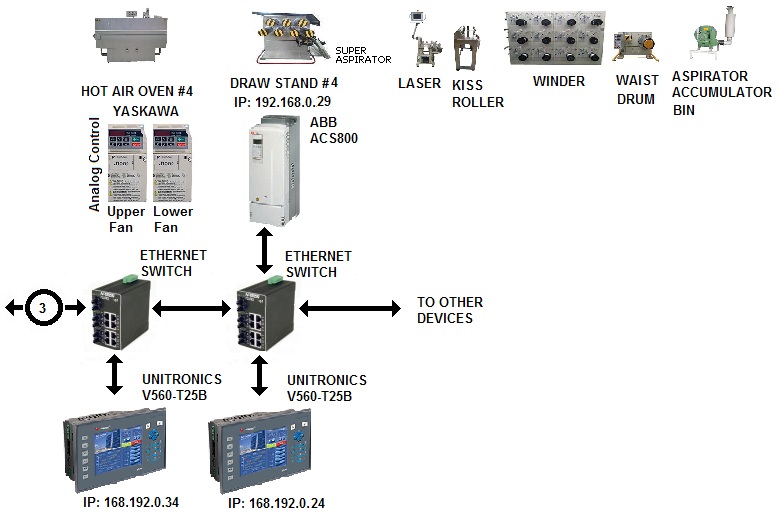

Downstream Equipment Continue...part 3

Refurbished Extrusion Machinery

If the cost of a new extrusion system is not justifiable, we offer affordable refurbishing services of your existing extruder and downstream equipment. In combination with new and refurbished equipment the cost savings could be significant compared to a new line. Our upgrades intend to meet all safety and environmental regulations.

From a Old System [Extruder Only]

To a Complete New System [Extruder & Spin Pump]